Why Is There a Problem?

I’ve spent 25 years in Architecture and Engineering firms on the design side of construction. For the last 4 years, I have been focusing on the construction side, providing BIM Coordination services for Electrical Contractors. As a result, I have a unique perspective on the design/construction industry. It amazes me how quickly Architects and Engineers can develop either a good or bad reputation for their modeling capabilities by the Contractor’s BIM Coordination teams. Typically, one of the first questions I hear asked by members of the BIM Coordination team is, “Who is the Architect/Engineer?”. We know that the quality of the Design Model greatly impacts the required effort in beginning coordination and throughout.

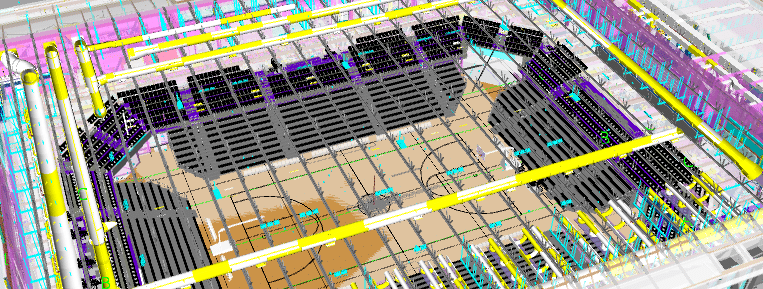

I always enjoyed working with the design team to coordinate our designs and deliver a Revit model that could continue to “live” past the bidding phase. Now, I am often surprised at the quality of the models I’ve received from design teams to carry into the construction side of the project. Designers, in general, seem to build the model with the intent of delivering PDF drawings to convey the design intent.

Although the drawings are complete, the construction effort relies on the models to be accurate, not just correct on a printed drawing. When utilizing Navisworks to coordinate the design for construction, an accurately modeled project from the design team is critical to meeting tightening project schedules.

How Can It Be Improved?

Speaking from an Electrical perspective, accurate coordination requires a consistent design model. Here are some things that make for a great design model to begin coordination:

- Modeling not only equipment, but equipment with required NEC clearances

- Power, Fire Alarm, and Lighting devices not only modeled in the correct location (X,Y), but at the accurate elevations (Z)

- Modeling with Revit families that provide parameters for modification

- Typically designers are modeling for basis of design. In construction, we are coordinating with the actual, submittal approved, products. This typically requires an adjustment in size

- Families for lighting and equipment that allow for a clearance to be added and modified is very helpful

- For example, we not only need the accurate size of a 2×4 lighting fixture, but also a clearance behind the fixture to allow for installation (a duct can not be flat against the back of a light fixture)

- For pendant mounted light fixtures, modeling the aircraft cable, stem, or chain allows for these to clearly be hung, rather than just floating in space

The Benefits of a Good Model

When the contractor receives an accurate design model it then allows them to focus on the details of coordination. Having to replace families, re-host content, and confirming elevations of devices cuts time out of the already progressive construction schedule. Also, this benefits the Design Team, enabling the Coordination Team to use in whole what was originally designed rather than having to rebuild the model with usable families and content.

Now more than ever, it is critical that the design team and construction team work together with the best interest of the project and the owner in mind. Engineers and Architects that develop a reputation for delivering quality design models will find Contractors that are eager to work on their projects.